How an Optical Fibre Diameter Analyser Improves the Performance of Fibre Optic Networks

How an Optical Fibre Diameter Analyser Improves the Performance of Fibre Optic Networks

Blog Article

Exactly How an Optical Fibre Diameter Analyser Improves Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre production procedures represents a significant advancement in top quality control methods. By offering real-time, specific measurements of Fibre diameters, this modern technology attends to the vital need for uniformity in manufacturing criteria. With its ability to promptly identify inconsistencies and timely rehabilitative steps, the analyser not just improves product integrity but additionally adds to general operational effectiveness. As sectors increasingly focus on high quality and compliance, understanding the complete influence of such developments comes to be important. What effects could this have for the future of Fibre production?

Significance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is critical in the field of optical Fibre modern technology, as it straight affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying ability, depletion, and general transmission effectiveness. Precision in determining Fibre Diameter ensures that the optical residential or commercial properties are preserved within defined resistances, which is crucial for ideal signal integrity.

Variations in Fibre Diameter can lead to enhanced losses due to spreading and modal dispersion, impacting the top quality of information transmission. In high-speed communication systems, such discrepancies can result in substantial deterioration of signal quality, leading to information errors and lowered efficiency. Regular Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are indispensable parts of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily rely on precise Diameter dimensions to ensure conformity with industry criteria. By executing durable measurement methods, producers can boost product integrity, minimize waste, and enhance overall system performance. Hence, the significance of Fibre Diameter dimension can not be overstated, as it functions as a cornerstone in the improvement of optical Fibre technology and its applications in contemporary interaction networks.

Exactly How the Analyser Functions

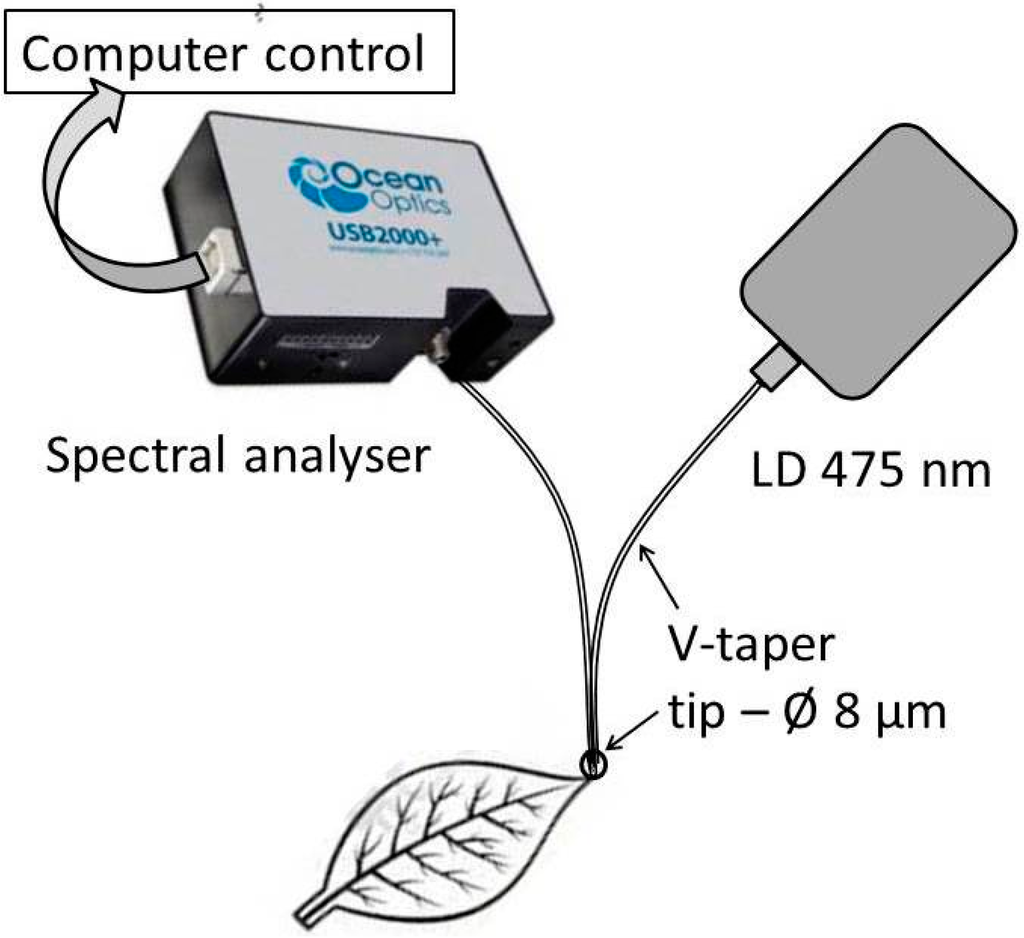

The effective measurement of Fibre Diameter relies upon innovative logical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser modern technology and advanced image processing formulas to properly evaluate the Diameter of fibres as they are generated

Initially, a laser beam of light is guided at the relocating Fibre, creating a cross-sectional shadow. The analyser catches this darkness making use of high-resolution cameras positioned tactically along the manufacturing line. The recorded images are then processed in real-time to figure out the Fibre's Diameter with exceptional accuracy.

The system utilizes sophisticated algorithms that represent numerous variables, consisting of variants in light strength and ecological problems, to boost dimension integrity. It can detect minute changes in Diameter, such as variations that could take place throughout the production procedure.

Additionally, the analyser is qualified of dealing with multiple fibers simultaneously, boosting throughput without jeopardizing precision. By supplying immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in preserving stringent top quality control criteria, making sure that the final product meets sector requirements and client requirements.

Advantages of Real-Time Tracking

While conventional approaches of checking Fibre Diameter typically involve taxing post-production checks, real-time tracking substantially improves the performance and high quality of optical Fibre production. optical fibre diameter analyser. This proactive strategy enables producers to identify inconsistencies in Fibre Diameter as they occur, instead of waiting until manufacturing is complete to examine quality

By continually determining the Diameter during manufacturing, producers can make certain that the fibres satisfy stringent specs, bring about decreased irregularity and improved consistency. Real-time surveillance also makes it more tips here possible for immediate restorative activities to be taken, minimizing waste and stopping malfunctioning fibres from going into the supply chain.

Additionally, this innovation facilitates improved information collection and evaluation, providing insights right into manufacturing trends and potential areas for improvement. Such data-driven decision-making equips makers to maximize processes and maintain high requirements of quality assurance.

On top of that, real-time monitoring fosters a culture of constant enhancement click now within the production atmosphere. Workers are a lot more involved when they can see the influence of their operate in real-time, leading to heightened accountability and a commitment to excellence. In general, the application of real-time surveillance systems in optical Fibre production converts to premium item top quality and raised consumer satisfaction.

Influence On Production Effectiveness

Applying optical Fibre Diameter analysers substantially improves production efficiency by improving the manufacturing procedure. These tools promote continual surveillance of Fibre Diameter, enabling producers to spot discrepancies in real-time. By identifying inconsistencies without delay, assembly line can be changed rapidly, minimizing downtime and decreasing the likelihood of generating malfunctioning products.

Furthermore, the assimilation of these analysers right into the production operations makes it possible for much better resource allocation. With exact Diameter measurements, drivers can optimize product usage, ensuring that sources are not lost on flawed fibers. Recommended Reading This precision also adds to much less ditch and rework, eventually lowering manufacturing costs.

The automation given by optical Fibre Diameter analysers lowers reliance on hand-operated evaluations, which are frequently taxing and prone to human error. Consequently, employees can concentrate on more strategic tasks, boosting overall efficiency.

Moreover, the data created from these analysers can inform procedure renovations and help with better decision-making. By examining fads in Fibre Diameter variants, manufacturers can execute aggressive measures to improve manufacturing techniques and maintain constant high quality. In recap, optical Fibre Diameter analysers play an important role in increasing manufacturing performance, leading to higher high quality result and increased success.

Study and Success Stories

Throughout various industries, study highlight the transformative influence of optical Fibre Diameter analysers on manufacturing procedures. One prominent example is a leading telecommunications company that dealt with difficulties with irregular Fibre sizes, bring about raised rejection rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time monitoring of Fibre measurements, causing a 30% decrease in issues and significant price financial savings.

Furthermore, a research study institution concentrating on sophisticated products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capability to give detailed understandings into Fibre consistency allowed the development of ingenious products with enhanced efficiency qualities.

These success tales underscore the necessary role of optical Fibre Diameter analysers in improving quality assurance, enhancing manufacturing efficiency, and driving advancement across diverse markets.

Verdict

In verdict, the Optical Fibre Diameter Analyser plays an essential role in enhancing high quality control within Fibre production. As shown via numerous instance researches, the analyser confirms essential for achieving superior item top quality in Fibre production.

The implementation of optical Fibre Diameter analysers enabled for stringent high quality control, ensuring that the generated fibres satisfied exacting industry requirements.In conclusion, the Optical Fibre Diameter Analyser plays a pivotal function in enhancing high quality control within Fibre production.

Report this page